|

|

|

|

| Rheological Properties |

| Melt Volume Rate 220 °C/10 kg | *** 1133 | cm?/10 min | 3.5 |

| Mechanical Properties |

| Izod Notched Impact Strength, 4mm bar, 0.25mm Notch Radius, 23 °C | *** 180/A | kJ/m2 | 60 |

| Izod Notched Impact Strength, 4mm bar, 0.25mm Notch Radius, -30 °C | *** 180/A | kJ/m2 | 15 |

| Charpy Notched Impact Strength, 23° C | *** 179 | kJ/m? | 60 |

| Tensile stress at yield, 23° C | *** 527 | MPa | 53 |

| Tensile strain at yield, 23° C | *** 527 | % | 4.9 |

| Tensile Modulus | *** 527 | MPa | 2300 |

| Tensile Creep Modulus (1000h) | *** 899 | MPa | 1600 |

| Tensile Creep Modulus (1h) | *** 899 | MPa | 2000 |

| Elongation at Break (MD) |

| % | >50 |

| Flexural Strength | *** 178 | MPa | 78 |

| Ball Indentation Hardness | *** 2039-1 | MPa | 95 |

| Thermal Properties |

| Vicat Softening Temperature VST/B/50 (50°C/h, 50N) | *** 306 | °C | 120 |

| Vicat Softening Temperature, VST/A/50 (50°C/h, 10N) | *** 306 | °C | 136 |

| Heat Deflection Temperature; (annealed) method Af, 1.8 MPa | *** 75 | °C | 106 |

| Heat Deflection Temperature; (annealed) method Bf, 0.45 MPa | *** 75 | °C | 125 |

| Linear Mold Shrinkage | *** 294-4 | % | 0.3 - 0.7 |

| Coefficient of Linear Thermal Expansion | *** 11359 | 10-6/°C | 70 - 90 |

| Thermal conductivity | DIN 52612-1 | W/(m K) | 0.17 |

| Electrical Properties |

| Dielectric Constant (100 Hz) | IEC 60250 | - | 3.4 |

| Dissipation Factor (100 Hz) | IEC 60250 | - | 60 |

| Dissipation Factor (1 MHz) | IEC 60250 | - | 150 |

| Volume Resistivity | IEC 60093 | Ohm*m | 1E12 |

| Surface Resistivity | IEC 60093 | Ohm | 1e+013 |

| Other Properties |

| Density | *** 1183 | kg/m3 | 1150 |

| Water absorption saturated at 23°C | *** 62 | % | 0.9 |

| Processing |

| Processing (Melt) Temperature | *** 294 | °C | 260 - 300 |

| Mold Temperature | *** 294 | °C | 80 |

| Injection velocity | *** 294 | mm/s | 200 |

| Drying Temperature |

| °C | 100 - 110 |

| Drying Time |

| hr | 2 - 4

|

挤出ASA KR2863C 室外耐候专用

¥20.60

挤出ASA KR2863C 室外耐候专用

¥20.60

供应ASA 德国巴斯夫 KR2866C 高韧性树脂

¥25.60

供应ASA 德国巴斯夫 KR2866C 高韧性树脂

¥25.60

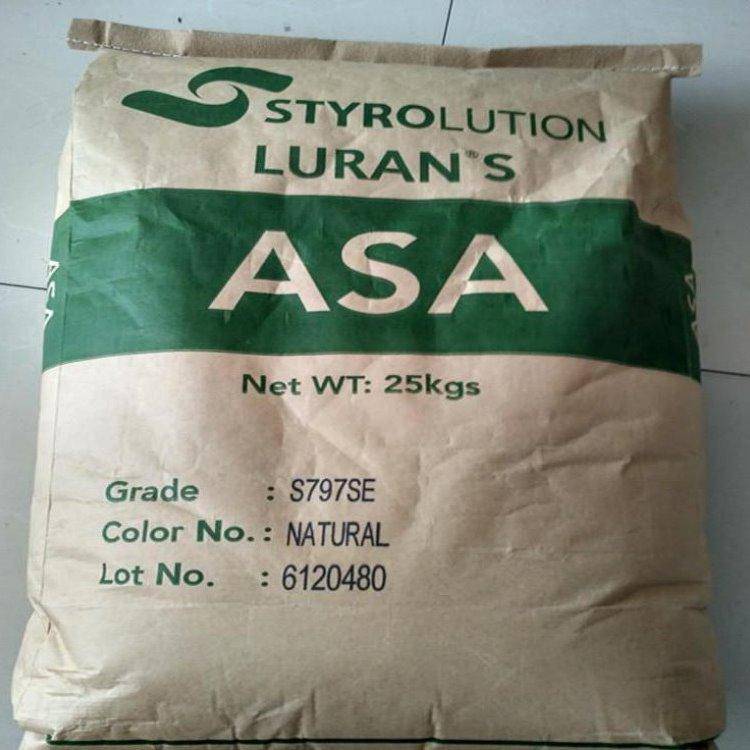

型材挤出ASA 776SE 巴斯夫Luran 776SE

¥25.60

型材挤出ASA 776SE 巴斯夫Luran 776SE

¥25.60

户外材料ASA 776SE BK 高流动 耐高温

¥16.60

户外材料ASA 776SE BK 高流动 耐高温

¥16.60

抗紫外线ASA 巴斯夫 797SUV 抗冲击 颗粒料

¥20.60

抗紫外线ASA 巴斯夫 797SUV 抗冲击 颗粒料

¥20.60

耐高温ASA 757R 室外耐候专用 巴斯夫

¥23.60

耐高温ASA 757R 室外耐候专用 巴斯夫

¥23.60