厂家直供 不锈钢格兰头 接头 【bimed】固定头

¥23.00

厂家直供 不锈钢格兰头 接头 【bimed】固定头

¥23.00

MB壁挂式不锈钢配电箱 威图户外不锈钢配电箱现货供应

¥680.00

MB壁挂式不锈钢配电箱 威图户外不锈钢配电箱现货供应

¥680.00

进口电缆防水接头 不锈钢接头 扶手接头 花园管接头

¥16.00

进口电缆防水接头 不锈钢接头 扶手接头 花园管接头

¥16.00

厂家直供 不锈钢格兰头 接头 【bimed】固定头

¥23.00

厂家直供 不锈钢格兰头 接头 【bimed】固定头

¥23.00

MB壁挂式不锈钢配电箱 威图户外不锈钢配电箱现货供应

¥680.00

MB壁挂式不锈钢配电箱 威图户外不锈钢配电箱现货供应

¥680.00

进口电缆防水接头 不锈钢接头 扶手接头 花园管接头

¥16.00

进口电缆防水接头 不锈钢接头 扶手接头 花园管接头

¥16.00

本店商品均不含税点金额,如需开发票请咨询客户添加税点,如直接备注开票未咨询客服+税点的,本店有权不开发票。

产品展示

产品介绍

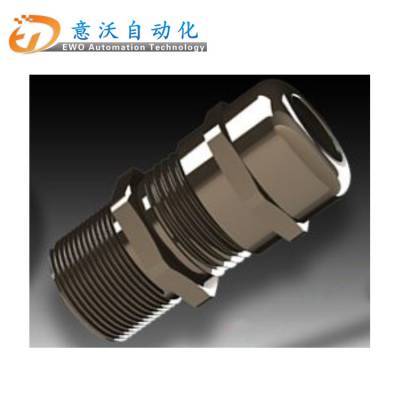

bimedEMC第四代防电磁屏蔽接头

Thesecableglandsaredevelopedaccordingtoendusers'requirements.Theirfeaturescanbesummarizedasfollows: ·Easyinsertionofthecablefromthetwosidesofthegland. |

TechnicalDetails | ||

Material | ||

Body | Brass,Nickelplated | |

Cap | Brass,Nickelplated | |

ContactSpr. | SpecialCopperAlloy | |

Clamp.Insert | Polyamide6V2 | |

Seal | Chloroprene | |

O-ring | NBR | |

OperatingTemperature | ||

Permanent | -20°Cupto+100°C | |

Intermittent | -40°Cupto+300°C | |

Benefits | ||

Suitableforhighestdemandsoftodaystechnology | ||

Easytoassemble | ||

Easyhandling | ||

Watertight | ||

Strainrelief | ||

Accessories | ||

Locknuts | ||

Remarks | ||

ManufacturedaccordingtotherequirementsofEN50262 | ||

22,0

TechnicalInformation | Codes | PackingInformation | ||||||||

ThreadType | ClampingRange min-maxmm | ShieldDiameter | TLmm | TDmm | SW1mm | SW2mm | Max. | InnerPack | Box/Min.OQ | |

METRICTHREADAttachmentThreadEN60423 | ||||||||||

M12X1,5 | 3,0-6,5 | 2,0-5,0 | 6,0 | 12 | 14,0 | 14,0 | 28,0 | BMEM-ES(M12T) | 50 | 2.000 |

M16X1,5 | 5,0-10,0 | 3,5-8,0 | 6,0 | 16 | 20,0 | 20,0 | 33,0 | BMEM-E1(M16T) | 50 | 1.000 |

M20X1,5 | 6,0-12,0 | 4,5-10,0 | 6,0 | 20 | 22,0 | 22,0 | 32,0 | BMEM-E2S(M20T) | 50 | 800 |

M20X1,5 | 7,5-14,0 | 5,5-11,5 | 8,0 | 20 | 24,0 | 24,0 | 39,5 | BMEM-E2(M20T) | 50 | 600 |

M25X1,5 | 10,0-18,0 | 7,0-14,0 | 8,0 | 25 | 30,0 | 30,0 | 43,0 | BMEM-E3(M25T) | 25 | 400 |

M32X1,5 | 16,0-25,0 | 12,0-20,0 | 9,0 | 32 | 40,0 | 40,0 | 53,0 | BMEM-E4(M32T) | 25 | 250 |

M40X1,5 | 22,0-32,0 | 18,0-27,0 | 9,0 | 40 | 50,0 | 50,0 | 60,5 | BMEM-E5(M40T) | 20 | 140 |

M50X1,5 | 30,0-38,0 | 26,0-34,0 | 9,0 | 50 | 58,0 | 58,0 | 73,0 | BMEM-E6(M50T) | 12 | 72 |

M63X1,5 | 34,0-44,0 | 30,0-40,0 | 14,0 | 63 | 64,0 | 68,0 | 59,0 | BMEM-E7(M63T) | 12 | 72 |

M63X1,5 | 37,0-53,0 | 33,0-49,0 | 10,0 | 63 | 75,0 | 75,0 | 72,0 | BMEM-E7L(M63T) | 12 | 72 |

PGTHREADAttachmentThreadDIN40430 | ||||||||||

Pg7 | 3,0-6,5 | 2,0-5,0 | 6,0 | 12,50 | 14,0 | 14,0 | BSEM-E1(Pg7T) | 50 | 2000 | |

Pg9 | 4,0-8,0 | 3,0-4,0 | 6,0 | 15,20 | 17,0 | 17,0 | 23,0 | BSEM-E2(Pg9T) | 50 | 1500 |

Pg11 | 5,0-10,0 | 3,5-8,0 | 6,0 | 18,60 | 20,0 | 20,0 | 28,0 | BSEM-E3(Pg11T) | 50 | 1.000 |

Pg13,5 | 6,0-12,0 | 4,5-10,0 | 6,0 | 20,40 | 22,0 | 22,0 | 26,0 | BSEM-E4(Pg13,5T) | 50 | 800 |

Pg16 | 7,5-14,0 | 5,5-11,5 | 8,0 | 22,50 | 24,0 | 24,0 | 30,0 | BSEM-E5(Pg16T) | 25 | 600 |

Pg21 | 10,0-18,0 | 7,0-14,0 | 8,0 | 28,30 | 30,0 | 30,0 | 34,0 | BSEM-E6(Pg21T) | 25 | 400 |

Pg29 | 16,0-25,0 | 12,0-20,0 | 9,0 | 37,00 | 40,0 | 40,0 | 41,0 | BSEM-E7(Pg29T) | 25 | 250 |

Pg36 | 22,0-32,0 | 18,0-27,0 | 9,0 | 47,00 | 50,0 | 50,0 | 48,0 | BSEM-E8(Pg36T) | 20 | 140 |

Pg42 | 30,0-38,0 | 26,0-34,0 | 9,0 | 54,00 | 58,0 | 60,0 | 49,0 | BSEM-E9(Pg42T) | 10 | 100 |

Pg48 | 34,0-44,0 | 30,0-40,0 | 14,0 | 59,30 | 64,0 | 68,0 | 52,0 | BSEM-E0(Pg48T) | 5 | 50 |

NPTTHREADAttachmentThreadANSIB1.20.1(DimensionsisInch) | ||||||||||

NPT1/4" | 0,118-0,255 | 0,078-0,196 | 0,236 | 1/4 | 0,551 | 0,551 | 1,102 | BNEM-ES(NPT1/4"T) | 50 | 2.000 |

NPT3/8" | 0,196-0,393 | 0,137-0,314 | 0,236 | 3/8 | 0,787 | 0,787 | 1,338 | BNEM-E1(NPT3/8"T) | 50 | 1.000 |

NPT1/2" | 0,236-0,472 | 0,177-0,393 | 0,314 | 1/2 | 0,866 | 0,866 | 1,259 | BNEM-E2S(NPT1/2"T) | 50 | 800 |

NPT1/2" | 0,295-0,551 | 0,216-0,452 | 0,314 | 1/2 | 0,944 | 0,944 | 1,496 | BNEM-E2(NPT1/2"T) | 50 | 600 |

NPT3/4" | 0,393-0,708 | 0,275-0,551 | 0,314 | 3/4 | 1,181 | 1,181 | 1,653 | BNEM-E3(NPT3/4"T) | 25 | 400 |

NPT1" | 0,629-0,984 | 0,472-0,787 | 0,354 | 1 | 1,574 | 1,574 | 1,968 | BNEM-E4(NPT1"T) | 25 | 250 |

NPT11/4" | 0,866-1,259 | 0,708-1,062 | 0,354 | 11/4 | 1,968 | 1,968 | 2,244 | BNEM-E5(NPT11/4"T) | 20 | 140 |

NPT11/2" | 1,181-1,496 | 1,023-1,338 | 0,354 | 11/2 | 2,283 | 2,362 | 2,637 | BNEM-E6(NPT11/2"T) | 10 | 100 |

NPT2" | 1,338-1,732 | 1,181-1,574 | 0,551 | 2 | 2,519 | 2,677 | 2,716 | BNEM-E7(NPT2"T) | 5 | 50 |

公司介绍

The Bimed company has started its activity in 1978 as a medical and mechanical components manufacturer. After various developmentand reorganization steps during its life, Bimed has today become a large organization working in a 15,000 square meter facility with a staff of 300 people. 16 constitute the quality assurance department and 10 for the research and development division. By adding precision engine spindles and other mechanical parts to the production line, the company diversified its products. Our products can be classified as follows:

Cable fitting elements, as plastic and metallic cable glands

Pressure balance elements or ventilation plgs

Plastic connectors for the white and automotive industries

Gas springs for the automotive and furniture industries

Disposable medical products

Various custom products as requested by our customers

Bimed manufactures cable fitting elements which are designed for multipurpose applications in electrical, electronic and automotive industries. Our production capacity is supported by both manual and fully automated assembly lines. All our products conform to the relevant international and national standards of the end user countries. Tight control is imposed at all the stages of the production process and all the non-conformities are immediately eliminated. To achieve this, a full traceability system is developed in accordance with the EN *** 9001:2008 standard. As aresult,

Bimed has been able to establish an international reputation for its consistently high quality production standards. Bimed is constantly working to achieve customer satisfaction, by meeting requested requirements with its standard and customized products. Most often, our research and development department produces completely new items in accordance with client demands. These activities help us gain the praise and high appreciation of our customers.

With a worldwide market base, the Bimed distribution network has been established to ensure that the needs of this global market are well understood and fully satisfied. Our products have been expanded to and distributed in more than 30 countries. Bimed has a merit-based leadership in the cable gland and connector sector established on its reputation for quality and innovation. This philosophy has been instrumental in the development of a product line that is constantly growing to reflect the changing industry needs and advancements in technology.

With an active research and development program, Bimed has launched several new classes of cable glands for use in specific applications. These are produced in brass, stainless steel, well-known plastics and newly engineered plastics that meet severe working conditions. All our new products are submitted to the relevant accredited test bodies for approval. In general, all the new products introduced by Bimed are designed to give the end users significant advantages especially in assembly simplifications that allow for greater protection against possible damages to the underlying cables and equipment.

With the above resume about Bimedwe intend to emphasize the Bimed production philosophy and let it serve as certification for the large product line manufactured by all our divisions.

在线问

在线问