熔喷料PP中石化茂名Y1500 95-99级专用熔喷原料

¥35.00

熔喷料PP中石化茂名Y1500 95-99级专用熔喷原料

¥35.00

PC+ABS T45德国拜耳(T45)(T45)电镀级

¥18.00

PC+ABS T45德国拜耳(T45)(T45)电镀级

¥18.00

熔喷料PP中石化茂名Y1500 95-99级专用熔喷原料

¥35.00

熔喷料PP中石化茂名Y1500 95-99级专用熔喷原料

¥35.00

PC+ABS T45德国拜耳(T45)(T45)电镀级

¥18.00

PC+ABS T45德国拜耳(T45)(T45)电镀级

¥18.00

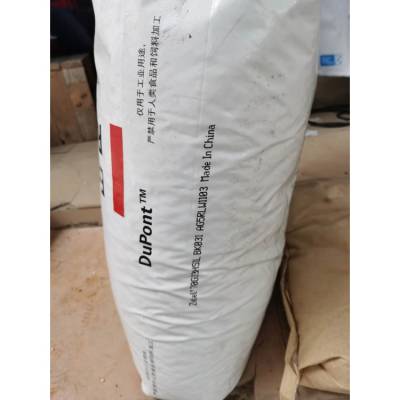

防火PA66 FR50美国杜邦/FR50阻燃V0级 玻纤25%

防火PA66 FR50美国杜邦/FR50阻燃V0级 玻纤25%

专业供应加碳纤PA66;耐高温PA66;医疗级PA66;无卤PA66;改性塑料PA66;导电PA66;高通明PA66;环保PA66;阻燃PA66;高抗冲击PA66;PA66塑胶原料;PA66物性;PA66代价;高耐油性PA66;高刚性PA66;PA66塑料;食品级PA66;PA66抗UV;无溴PA66;PA66资料;防火PA66;抗紫外线PA66;***脱模PA66;加纤PA66;纯树脂原料PA66;可为客户提供有关报告证明 性能测试报告,如:MSDS、SGS(RoHS)、FDA、ASTM或***物性资料,***证明,COA,UL黄卡等!!

pa66美国杜邦8018 玻纤增强14%超韧级

pa66美国杜邦st801,st801a耐低温,耐韧性

pa66美国杜邦st801aw,st801ahs超韧级,耐油性

pa66美国杜邦103hsl热稳定级

pa66美国杜邦103fhs 注塑级 热稳定级

pa66美国杜邦fr50玻纤25%阻然v0级

pa66美国杜邦fr15纯树脂,阻然vo级

pa66美国杜邦fr10纯树脂,阻然v0级

pa66美国杜邦fr7025v0,fr7026防火v0级 72g33hs1l 7304 nc010

pa66美国杜邦fe5313 fr52g20lx 72g33hs1l标准粘度 抗磨损

pa66美国杜邦fr16,fr60,fr70,防火阻燃v-0等级

pa66美国杜邦fr52g30bl 30%玻纤,阻然

pa66美国杜邦70g13l玻纤13% 高强度

pa66美国杜邦70g13hs1l玻纤13% 高强度

pa66美国杜邦70g43l玻纤43% 高强度

pa66美国杜邦70g33l 70g33玻纤33% 高强度

PA性能的主要缺点:

1.易吸水。吸水性大,饱和水可以达到3%以上.一定的程度上影响尺寸稳定性和电性能,特别是薄壁件增厚影响较大;吸水亦会大大降低塑料的机械强度。在选材时,应顾及使用环境及与别的元件的配合精度的影响。纤维增强可降低树脂吸水率,使其能在高温、高湿下工作。尼龙与玻璃纤维亲合性十分良好。常用于制作梳子、牙刷、衣钩、扇骨、网袋绳、水果外包装袋等等。***性,但不可长期与酸碱接触。值得注意的是,加入玻纤后,尼龙的抗拉强度可提高2倍左右,耐温能力也相应得到提高.

2.耐光性较差。在长期偏高温环境下会与空气中的氧发生氧化作用,开始时颜色变褐,继面破碎开裂。

3.注塑技术要求较严:微量水分的存在都会对成型质量造成很大损害;因热膨胀作用使制品尺寸稳定性较难控制;制品中尖角的存在会导致应力集中而降低机械强度;壁厚如果不均匀会导致制件的扭曲、变形;制件后加工时设备精度要求高。

4.会吸收水、醇而溶胀,不耐强酸及氧化剂,不能作耐酸材料使用。

Huayun plastic company pure resin raw material PA66 injection speed: high-speed on the enhanced information should be slightly lower. Runner and gate: Because of PA66's short agglutination time, gate orientation is important. Gate aperture should not be less than 0.5 * T here t for the thickness of plastic parts. If the use of warm runner gate standard should be smaller than the use of conventional runner. If the submerged gate is used, the small diameter of the gate should be 0.75 mm. Typical uses PA66 is more widely used in the automotive industry, instrument housing and other requirements have impact resistance and high strength requirements of the product. Application Plan PA66 is more widely used in automotive industry, instrument housing and other products requiring impact resistance and high strength. Frequently asked questions, overflow Flash, bubble, SHRINK MARK, fusion mark, scorch and black line, silver wire and speckle, appearance scratch, appearance fog and speckle, scorch color and impurity, burn black, poor luster, cracking white, uneven color, weak, delamination, warping deformation, bad demoulding, severe mold corrosion. Pure resin raw material PA66 polyamide 66 or Nylon 66, nylon66. PA66 has a high melting point in polyamide materials. It is a semicrystalline-crystalline material or opaque milky crystalline polymer with plasticity. PA66 also maintains its strength and stiffness at higher temperatures. PA66 is still hygroscopic after molding, the degree of which depends primarily on the composition of the material, wall thickness and environmental conditions. It is important to consider the effect of hygroscopicity on a number of stabilities when describing products. In order to advance the mechanical properties of PA66, various modifiers are often used. Glass is a common additive and is sometimes used for impact resistance in synthetic rubber, such as EPDM and SBR. PA66 has a low viscosity and therefore a good fluidity, but not as good as PA6. This property can be used to machine very thin components. Its viscosity is very flexible to temperature changes. PA66 is resistant to many solvents, but less resistant to acids and other chlorinated agents.

在线问

在线问