PA66 Ultramid A3WC8导电碳纤增强40%

- ¥39.90 25 - 499

- ¥39.50 ≥500

- Ultramid品牌

- 否是否进口

- 德国产地

***巴斯夫PA66 Ultramid A3WC8导电碳纤增强40%

Density | 1.33 | -- | g/cm | *** 1183 |

| Mechanical | Dry | Conditioned | Unit | Test Method |

Tensile Modulus | *** 527-2 | |||

23°C | 38100 | 27400 | MPa | |

80°C | 19400 | 17200 | MPa | |

120°C | 15200 | 13100 | MPa | |

150°C | 13500 | 11400 | MPa | |

Tensile Stress | *** 527-2 | |||

Break, 23°C | 295 | 255 | MPa | |

Break, 80°C | 203 | 168 | MPa | |

Break, 120°C | 155 | 130 | MPa | |

Break, 150°C | 130 | 110 | MPa | |

Tensile Strain | *** 527-2 | |||

Break, 23°C | 1.2 | 2.1 | % | |

Break, 80°C | 2.1 | 2.3 | % | |

Break, 120°C | 2.3 | 2.4 | % | |

Break, 150°C | 2.4 | 2.6 | % | |

Flexural Modulus(23°C) | 34700 | -- | MPa | *** 178 |

Flexural Stress(23°C) | 484 | -- | MPa | *** 178 |

| Impact | Dry | Conditioned | Unit | Test Method |

Charpy Notched Impact Strength | *** 179 | |||

-40°C | 9.0 | -- | kJ/m | |

23°C | 11 | -- | kJ/m | |

Charpy Unnotched Impact Strength | *** 179 | |||

-40°C | 81 | -- | kJ/m | |

23°C | 84 | -- | kJ/m | |

Notched Izod Impact Strength(-40°C) | 9.0 | -- | kJ/m | *** 180 |

| Thermal | Dry | Conditioned | Unit | Test Method |

Heat Deflection Temperature(1.8 MPa, Unannealed) | 256 | -- | °C | *** 75-2/A |

Melting Temperature (DSC) | 260 | -- | °C | *** 3146 |

***巴斯夫PA66 Ultramid A3WC8导电碳纤增强40%

在线问

在线问

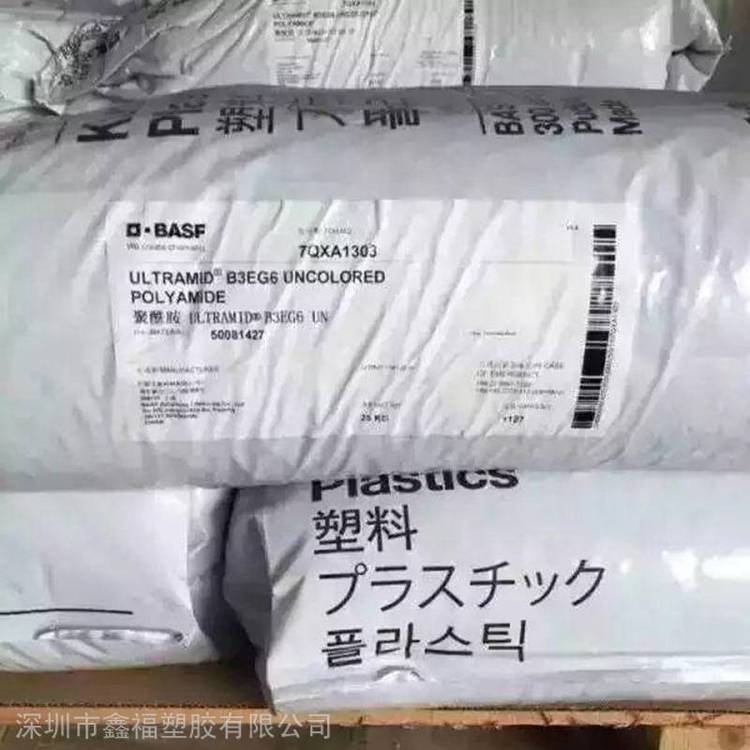

- Ultramid

- 否

- 德国

- 德国巴斯夫

- A3WC8

- 品牌经销

- 标准料

- PA66

- 注塑级

- 25KG/包

- 导电PA66