参数

- 增强15%产品特性

- 否是否进口

- 德国产地

广东 东莞

1天内发货

55000千克

产品详情

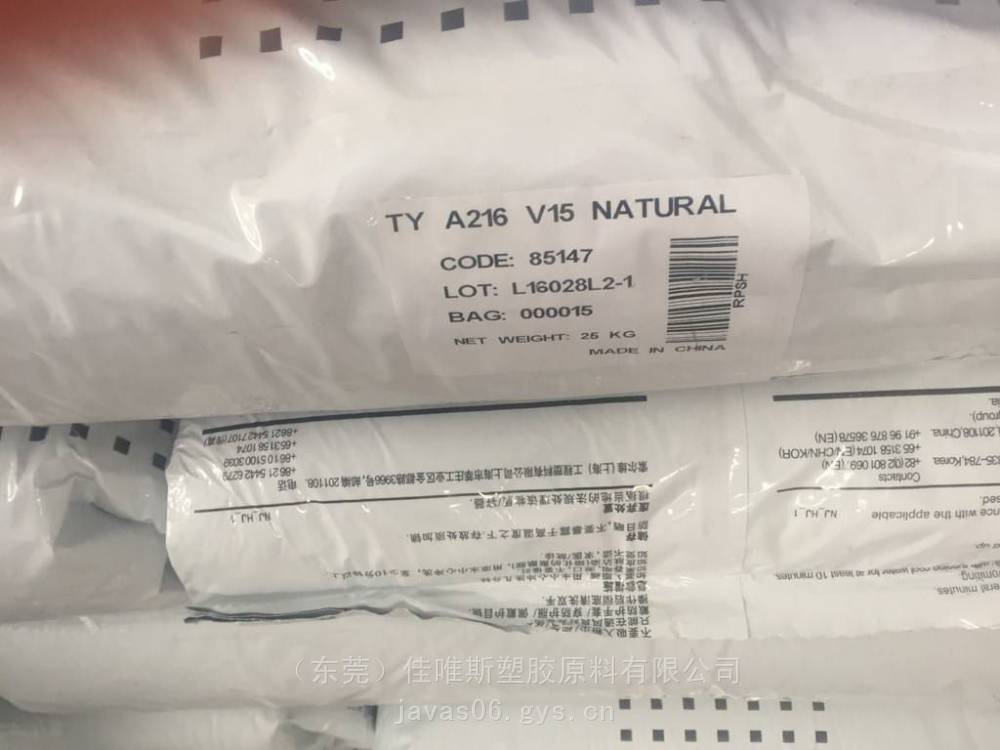

塑胶原料PA66德国巴斯夫A216V15玻纤增强15% 如需其它型号,欢迎电询15382847379,VX同号。

PA66德国巴斯夫A216V15物性表

| Ultramid®A 216 V15是一种聚酰胺66,用15%的玻璃纤维增强,用于注塑成型。该等级在热性能和机械性能之间提供了极好的结合。 |

产品描述 Product Description

加工条件:注塑

填料:玻璃纤维 15

| 技术参数 Technical Data | |||

|---|---|---|---|

PHYSICAL | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 吸水率 Water Absorption Water Absorption | |||

| 24 h,23℃ 24 h,23℃ | 1.1 | % | *** 62 |

| 平衡 equilibrium,23℃ Equilibrium equilibrium, 23 ℃ | 7 | % | *** 62 |

| 吸湿性 Moisture Absorption Moisture Absorption | 2.2 | % | *** 62 |

| 密度 Density Density | 1240 | kg/m³ | *** 1183 |

MECHANICAL | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 拉伸模量 Tensile Modulus Tensile Modulus | |||

| 干燥 dry Dry | 6200 | MPa | *** 527 |

| 湿润 cond. Wet Cond | 4300 | MPa | *** 527 |

| 拉伸强度 Tensile Strength Tensile Strength | |||

| 断裂 brk,干燥 dry Broken BRK, dry dry | 125 | MPa | *** 527-2 |

| 断裂 brk,湿润 cond. Broken BRK, wet Cond | 90 | MPa | *** 527-2 |

| 拉伸应变 Tensile Strain Tensile Strain | |||

| 干燥 dry Dry | 2.5 | % | *** 527 |

| 湿润 cond. Wet Cond | >10 | % | *** 527 |

| 弯曲模量 Flexural Modulus Flexural Modulus | |||

| 干燥 dry Dry | 5600 | MPa | *** 178 |

| 湿润 cond. Wet Cond | 3500 | MPa | *** 178 |

| 弯曲强度 Flexural Strength Flexural Strength | |||

| 干燥 dry Dry | 180 | MPa | *** 178 |

| 湿润 cond. Wet Cond | 125 | MPa | *** 178 |

IMPACT | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 简支梁缺口冲击强度 Charpy notched Impact strength Charpy Notched Impact Strength | |||

| 干燥 dry Dry | 5 | kJ/m² | *** 179/1eA |

| 湿润 cond. Wet Cond | 7.5 | kJ/m² | *** 179/1eA |

| 简支梁无缺口冲击强度 Charpy Unnotched Impact strength Charpy Unnotch Impact strength | |||

| 干燥 dry Dry | 35 | kJ/m² | *** 179/1eU |

| 湿润 cond. Wet Cond | 60 | kJ/m² | *** 179/1eU |

| 悬臂梁缺口冲击强度 Izod Notched Impact strength Izod Notched Impact strength | |||

| 干燥 dry Dry | 5 | KJ/m² | *** 180/1A |

| 湿润 cond. Wet Cond | 9 | KJ/m² | *** 180/1A |

| 干燥 dry Dry | 55 | J/m | ASTM D256 |

| 悬臂梁无缺口冲击强度 Izod Unnotched Impact strength Izod Unnotched Impact strength of cantilever beam | |||

| 干燥 dry Dry | 30 | KJ/m² | *** 180/1U |

| 湿润 cond. Wet Cond | 55 | KJ/m² | *** 180/1U |

THERMAL | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 热变形温度 HDT Hot deformation temperature HDT | |||

| 0.45 MPa 0.45 MPa | 255 | ℃ | *** 75-1/-2 |

| 1.80 MPa 1.80 MPa | 235 | ℃ | *** 75-1/-2 |

| 熔融温度 Melting temperature Melting temperature | 263 | ℃ | *** 11357-3 |

ELECTRICAL | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 表面电阻率 Surface Resistivity Surface Resistivity | |||

| 干燥 dry Dry | 6E15 | ohm | IEC 62631-3-2 |

| 湿润 cond. Wet Cond | 1E13 | ohm | IEC 62631-3-2 |

| 体积电阻率 Volume Resistivity Volume Resistance | |||

| 干燥 dry Dry | 1E13 | ohm·m | IEC 62631-3-1 |

| 湿润 cond. Wet Cond | 1E13 | ohm·m | IEC 62631-3-1 |

| 耐电强度 Electric strength Electric strength | |||

| d=2 mm,干燥 dry D=2 mm, dry | 31 | kV/mm | IEC 60243-1 |

| d=2 mm,湿润 cond. D=2 mm, moist cond | 20 | kV/mm | IEC 60243-1 |

| 耗散因数 Dissipation Factor Dissipation Factor | |||

| 干燥 dry Dry | 0.01 | E-4 | IEC 62631-2-1 |

| 湿润 cond. Wet Cond | 0.11 | E-4 | IEC 62631-2-1 |

| 相比漏电起痕指数 Comparative Tracking Index Compared Tracking Index | |||

| 测试液A test liquid A,干燥 dry Test liquid A, dry | 600 | IEC 60112 | |

| 测试液A test liquid A,湿润 cond. Test liquid A, wet cond | 600 | IEC 60112 | |

| 测试液B test liquid B,干燥 dry Test liquid B, dry | 525 | IEC 60112 | |

FLAME CHARACTERISTICS | 额定值 Nominal Value | 单位 Units | 测试方法 Test Method |

| 阻燃等级 Flame Class Rating Flame Class Rating | |||

| 1.6 mm 1.6 mm | HB | calss | IEC 60695-11-10 |

| 0.4 mm 0.4 mm | HB | calss | IEC 60695-11-10 |

| 灼热丝可燃性指数 Glow Wire Flammability Index(GWFI) Glow Wire Flammability Index (GWFI) | 650 | ℃ | IEC 60695-2-12 |

| 极限氧指数 Oxygen Index Oxygen Index | 24 | % | *** 4589-2 |

为您推荐

在线问

在线问

产品参数

- 增强15%

- 否

- 德国

- 德国巴斯夫

- A216V15

- 品牌经销

- 标准料

- PA66

- 注塑级

- 增强级、 高强度、 高流动、 高光泽

- 汽车部件、 电子电器部件、 家电部件、 电动工具配件

- 德国巴斯夫

- 25KG/包