5SHX06F6010相比传统的DCS,采用OCS工业光总线控制系统可以大幅节省自动化系统的投资成本,并大幅缩短项目建设周期,降低控制系统的维护成本。”这是杭州和利时自动化有限公司副总裁黄劲松,在笔者对和利时新近发布的OCS工业光总线控制系统做专访时给出的回答。 DCS,分布式控制系统,自20世纪70年代诞生以来,凭借其的技术优势,在炼油、石油、化工、电力、冶金等大型过程控制领域已经成为了标配。正因为如此,在过去的三四十年间,DCS 也未发生大的改变。 如今,技术飞速发展,IT、ICT、IoT等新兴技术给全社会带来了的变革。而这一次,光通信技术和软件定义被引入到了DCS,DCS进化为了OCS,无论是系统架构,还是控制器和I/O,都发生了质变,从而在项目成本、机柜间面积和实施周期等各方面都大大胜过了传统DCS。 那么什么是OCS?为何能变革传统的DCS?它用到了哪些技术?能够为用户带来哪些好处?适合于哪些应用场合呢?为此,CONTROL ENGINEERING China和黄劲松进行了一次深入的访谈。和DCS(Distributed Control System)类似,OCS是Industrial Optical Bus Control System的简称,中文称为工业光总线控制系统。OCS和DCS的大区别在于,OCS中采用了光纤作为控制器和I/O之间的网络传输介质,替代一直沿用的铜芯双绞线电缆。 传统控制系统,现场设备的信号传输到控制系统需要经过现场接线箱、电缆桥架、端子柜、安全栅 柜、I/O机柜等一系列中间环节才能完成。如图1所示。而OCS改变了传统DCS的系统架构,现场设备直接通过位于现场的工业光总线数据传输单元(iDTU)连接到远端的控制器,省却了一系列的中间环节。

We currently stock over 12000+ branded products.

---Invensys Foxboro:

I/A Series system, FBM(input / output modules) Sequence control, ladder logic control, Recalling accident treatment, The digital-to-analog converter input/output signal processing, Data munication and processing, and etc.

---Invensys Triconex:

Redundancy fault tolerant control system, Based on the three module redundancy (TMR) structure of the most modern fault-tolerant controller.

---Westinghouse:

OVATIONN system, WDPF system, WESStation system card.

---Modicon:

Quantum 140 Series processor, control card, Power module and so on.

---Rockwell Allen-Bradley:

Reliance, SLC500/1747/1746, MicroLogix/ 1761/ 1763/ 1762/ 1766/ 1764, pactLogix/1769/1768,Logix5000/1756/1789/1794/1760/1788, PLC-5/1771/1785 and etc.

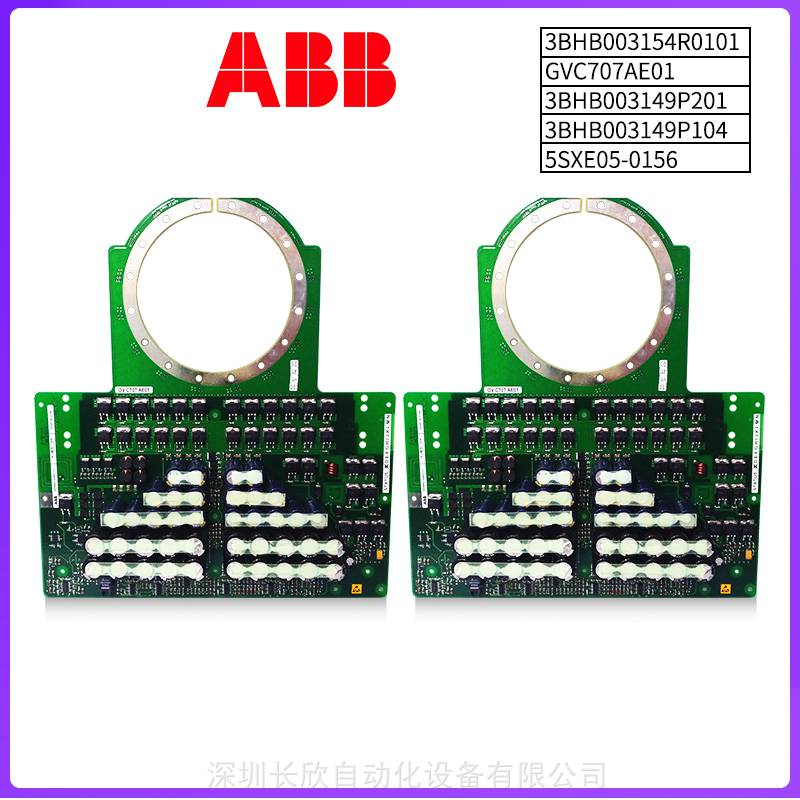

--- Industrial robot parts of DSQC series, Bailey INFI90, etc.

---Siemens: Siemens MOORE, Siemens Simatic C1, Siemens numerical control system, etc.

---Motorola: MVME162, MVME167, MVME1772 and MVME177 series.

Multiple technologies have emerged in recent years that are instrumental in driving the advancement of smart manufacturing and the Industrial IoT. These include advanced analytics, artificial intelligence (AI) and machine-learning (ML), operational intelligence, advanced robotics, cyber-physical systems and generative design for additive manufacturing. While each of these technologies is changing the face of manufacturing today, ARC Adv***ry Group research suggests that the Industrial IoT, connected smart assets, and especially the Digital Twin are having the most immediate and significant impact on how companies implement technologies that enable smart manufacturing.The basic concepts surrounding the digital twin have been defined, frameworks established, and continue to evolve due to technological advancements and more clearly defined business goals. The benefits have been evaluated and validated and industries are now moving into the implementation phase.

Today, production engineers are merging virtual engineering models with the physical equipment in an environment that allows for operational performance improvement as well as predictive maintenance of the equipment. Moreover, due to the advancement and evolution of enabling technologies like virtual simulation modeling and digital twin development platforms, we see renewed focus on the implementation of the digital twin and associated benefits that could be gained. Using digital twins that represent the product and production systems, manufacturers can reduce the time and cost associated with assembling, installing, and validating factory production systems. Additionally, implementing digital twins for asset management typically provides quantifiable benefits for maintaining equipment in the field.

IGBT模块5SHX08F4510品质服务DCS集散式控制系统备件

¥2968.00

IGBT模块5SHX08F4510品质服务DCS集散式控制系统备件

¥2968.00

可控硅IGBT模块5SHX14H4510数据采集和控制系统DCS系列供应

¥2968.00

可控硅IGBT模块5SHX14H4510数据采集和控制系统DCS系列供应

¥2968.00

IGBT模块5SHX19L6010可控硅系列PLC系统控制器备件供应

¥2968.00

IGBT模块5SHX19L6010可控硅系列PLC系统控制器备件供应

¥2968.00

ABB系列5SHY35L4510工控Plc系统备件可控硅IGBT模块供应

¥2968.00

ABB系列5SHY35L4510工控Plc系统备件可控硅IGBT模块供应

¥2968.00