AB罗克韦尔2711-K5A2 H供应DCS控制系统备件进口原装品质生活

¥2850.00

AB罗克韦尔2711-K5A2 H供应DCS控制系统备件进口原装品质生活

¥2850.00

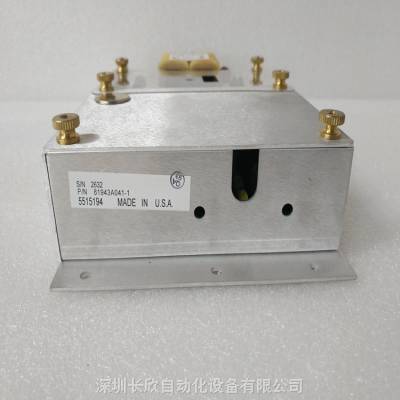

ABB系列81943A041-1供应DCS控制系统备件模块进口原装品质生活

- ¥3185.00 1个起批

- ¥2850.00 ≥2

- 产品保障产品特性

- 否是否进口

- 欧美产地

AB罗克韦尔2711-K5A2 H供应DCS控制系统备件进口原装品质生活

¥2850.00

AB罗克韦尔2711-K5A2 H供应DCS控制系统备件进口原装品质生活

¥2850.00

If you need our products, please contact us in advance------------同系列同品牌更多产品请留言喔。

------------我们及时为您服务!!

选择长欣的理由:

【深圳长欣自动化设备有限公司】经过十二年的快速发展,现已成为国内zui 具实力的工控备件商之一

产品应用于:电力、石油、矿井提升、港口、供热、燃气、供水、污水处理、冶金、造纸、纺织、化工、水利等现代化工业领域!

在工业生产中,工业机械手的运行是安全生产的重要保障。通过PLC在工业机械手自动化控制中的应用,能够有效提升机械手运行的稳定性。PLC系统具有自诊断功能,当被控制的机械手出现故障时,系统能够根据自诊断功能快速定位故障点,对于特定的故障还能够采取相应的动作,避免安全事故的发生。PLC系统还具有较好的电路保护功能,通过开关电源能够实现通断操作。在复杂的工业生产环境中,PLC的抗干扰能力和屏蔽能力,能够提升系统运行的可靠性。为了适应工业生产环境的需求,机械手需要根据生产所需而变换相应的程序。程序编写大多使用形象且简单的梯形图,机械手程序设计较为简单,不需要知识也可以编程,非常适应机械手的柔性化控制需求。一般情况下,机械手都是通过手臂的伸缩和上下移动来完成操作的,通过PLC实现对机械手的控制,主要工作流程如下:满足设备开启条件-通过检测元件确定工件的具体位置-机械手臂伸展抓取工件-机械手抓举工件上升或左右移动-机械手将工件放置于位置-机械手恢复至初始位置,在此流程下循环往复以实现机械手的自动化操作。在具体应用过程中,应该根据生产的实际需要和设计的动作控制流程选择PLC以及电器元件的型号,然后确定PLC的功能以及输入输出点的位置和数量,在此基础上进行PLC程序的编写。在工业机械手的自动化控制系统中,输入信号主要包括手动控制和自动控制选择按钮、设备启停按钮、检测机械手臂位置、确定工件具体位置的信号等,输出信号主要包括对气缸动作的控制以及对电机运行的控制。程序编写的好坏直接关系到机械手运行的度和效率,所以在编写程序之前要以机械手的运行原理为依据,同时对机械手的实际生产需求进行分析,然后进行程序的编写。在了解机械手的运行原理后,即可对PLC编程中需要注意的要点进行分析。机械手的机械运动主要是依靠气缸提供驱动力,而气缸的动作受到电磁阀的控制。机械手在执行抓取和放松动作时主要是由电磁阀的通断电控制的,在单线圈通电状态时,机械手可进行抓取动作,在单线圈断电状态时,机械手执行的是放松命令。机械手在工业生产的自动化作业时,长期反复执行同一套流程,为了***生产的安全进行,需要对机械手的动作流程进行严格的控制,只有在完全完成某一动作后,才可进入到下一动作。因为机械手从事的是循环动作,所以在完成一次动作流程后,机械手需要回归到原点,为下一任务的循环做好准备,机械手回归原位可由限位开关和电磁阀来控制。为了提升机械手控制的可靠性,控制系统会设定为自动和手动两种模式,系统的控制模式会有相应的指示灯显示控制模式的状态。通过对机械手的运行原理进行分析,能够提升PLC控制的性,进而确保机械手运行的安全性和稳定性。

The setting of the initial position is related to the accuracy of the manipulator control system. After each cycle action of the manipulator, it must return to the initial position. The initial position can be determined according to the actual production needs. The initial position does not have to be fixed at a specific position, but can be set by the control personnel according to the production needs. Pay attention to the state of the manipulator when setting the initial position. The manipulator should be in the normal stop state and the cylinder piston is in the retracted state. If the cylinder piston is extended, oxidation corrosion will occur due to external temperature and humidity, which will directly affect the air tightness of the cylinder and ultimately affect the operation control of the manipulator.Control system software and hardware design. The software and hardware design of the manipulator PLC control system is directly related to the system control quality, and is related to the accuracy and stability of the manipulator operation. In the hardware design of the control system, the automatic cycle control device can be designed according to the text content of ppl, the programmable control protocol can be selected, and the manipulator automatic controller can be designed in a closed cycle. When selecting a data acquisition board, pay attention to the speed and overall performance of data acquisition. If the analog data collected by the selected data acquisition board does not meet the operation requirements of the system, an analog-to-digital converter can be designed to convert the collected data. In the software design of the control system, the data of the automatic operation of the manipulator can be collected based on PLC. The selection of ports and the distribution of communication addresses can be designed according to the principle of corresponding design. After data collection, the corresponding communication network is used to limit the cycle times of the manipulator according to the high-level protocol. Based on PLC control technology, the advection current is transformed into AC according to the expression of signal filtering, and the terminal voltage data and signal are controlled by controlling the signal voltage value. Through the analysis of the obtained data, we can also analyze the energy consumption of the manipulator in different operating states, and then reduce the energy consumption of the automatic control of the manipulator through the optimization and adjustment of the control system.

ABB S-076N 3BHB009884R0021

ABB 5SDF1045H0002

ABB 3BHL000986P0006

ABB 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB 5SHY4045L0001 3BHB018162R0001 3BHE009681R0101 GVC750BE101

EATON MP3010

TRICONEX 2101

TRICONEX 2401

TRICONEX 2841

TRICONEX 2351

TRICONEX 2301

TRICONEX 2381

TRICONEX 2201

TRICONEX 3101

TRICONEX 3351

TRICONEX 3301

TRICONEX 3381

TRICONEX 3481

TRICONEX 3401

TRICONEX 3201

TRICONEX 2000418 1个 备货(黑色空槽盖子)

TRICONEX 2000417 1个 备货(黑色空槽盖子)

ABB BC810K02

A-B 2711-K9A8 F

A-B 1797-PS1E

ABB DSDO120 57160001-AK

MOTOROLA MVME2434

OPHIR NOVA II OPHIR

GE MX150

HONEYWELL MN7234A2008

PARKER ZETA6104

Lust LTi Drives LSH-050-2-45-320/T1.1R

GE UR8HH

EATON MP3010

ABB PPC90***E101

在线问

在线问

- 产品保障

- 否

- 欧美

- 否

- ABB

- 81943A041-1

- 标准V

- 标准

- 标准

- 模块

- 3658220

- DCS/PlC工控系统

- 原厂标准