光学镜头磨平用煅烧平板状氧化铝20um 25um

¥65.00

光学镜头磨平用煅烧平板状氧化铝20um 25um

¥65.00

风电叶片碳纤维拉挤板研磨用白刚玉280#电熔氧化铝研磨粉

¥9000.00

风电叶片碳纤维拉挤板研磨用白刚玉280#电熔氧化铝研磨粉

¥9000.00

光学镜头磨平用煅烧平板状氧化铝20um 25um

¥65.00

光学镜头磨平用煅烧平板状氧化铝20um 25um

¥65.00

风电叶片碳纤维拉挤板研磨用白刚玉280#电熔氧化铝研磨粉

¥9000.00

风电叶片碳纤维拉挤板研磨用白刚玉280#电熔氧化铝研磨粉

¥9000.00

硅锭切片后研磨表面用煅烧氧化铝粉晶体形状为片状 D50:10um,9um,8um

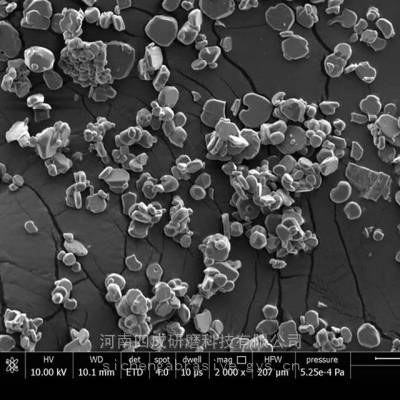

PRODUCT/产品: Platelet Calcined Aluminum Oxide /片状氧化铝

DESCRIPTION/产品介绍:

Platelet calcined alumina powder, also known as tabulated aluminum oxide grinding powder. It is named after its particle crystal structure being in the shape of scales/flat plates. The crystal form of flake alumina is α- Al2O3 has high hardness and grinding performance. In the electronics industry, polishing and polishing require high surface precision. To ensure precise grinding effects and yield, abrasive materials with sharp crystal shapes can no longer meet the requirements. The surface of the abrasive particles of flake/flat alumina is flat and smooth, and the diameter-to-thickness ratio of the particles can be adjusted by adjusting the synthesis method. Grinding semiconductor chips or other microelectronic components is less prone to scratches, greatly improving the yield of qualified chips. The production of platelet calcined alumina adopts a high-temperature calcined method to promote the lateral growth of crystals and form regular hexagonal powders with a tabulated structure. The suspension-treated aluminum oxide grinding powder of platelet shape gets a uniform particle size distribution. That ensures a fine grinding surface.

片状氧化铝又称为平板状氧化铝,因其颗粒晶型为鳞片/平板形状而得名。片状氧化铝晶型为α-Al2O3,具有很高的硬度和研磨性能。在电子行业的打磨抛光对表面的精细度要求高,为***精细的研磨效果和成品率,晶体形状为尖角状的磨料已经不能满足要求。片状/平板状氧化铝的磨粒表面平整光滑,颗粒的径厚比可以通过调整合成方法进行调节。研磨半导体晶片或其他微电子元件时不易产生划伤,大大提高了晶片的合格品率。片状氧化铝的生产采用高温烧结的方法,促使晶体进行横向生长,并形成具有片状结构的规则六角型粉体。水洗分选工艺的片状氧化铝粒度集中度高,有利于研磨表面的一致性。

CHEMICAL COMPOSITION/化学成分:

Item | Guarantee Value/***值(%) | Typical Value/典型值(%) |

Al2O3 | ≥99.0 | 99.45 |

Fe2O3 | ≤0.10 | 0.03 |

SiO2 | ≤0.20 | 0.08 |

Na2O | ≤1.0 | 0.22 |

PHYSICAL PROPERTIES/物理指标:

Specific Weight/比重 | Hardness/硬度 | Crystal Phase/晶相 | Crystal Shape/晶体形状 |

3.90 g/ cm3 | 9.0Mohs scale | α- Al2O3 | 平板状/Tabulated |

PARTICLE SIZE DISTRIBUTION/粒度分布:

SPEC./规格 | D3(um) | D50(um) | D94(um) |

HXTA45 | 50.5-56.2 | 33-38.5 | 20.7-24.5 |

HXTA40 | 39-44.6 | 27.7-31.7 | 18-20 |

HXTA35 | 35.4-39.8 | 23.8-27.2 | 15-17 |

HXTA30 | 28.1-32.3 | 19.2-22.3 | 13.4-15.6 |

HXTA25 | 24.4-28.2 | 16.1-18.7 | 9.6-11.2 |

HXTA20 | 20.9-24.1 | 13.1-15.3 | 8.2-9.8 |

HXTA15 | 14.8-17.2 | 9.4-11 | 5.8-6.8 |

HXTA12 | 11.8-13.8 | 7.6-8.8 | 4.5-5.3 |

HXTA09 | 8.9-10.5 | 5.9-6.9 | 3.3-3.9 |

HXTA05 | 6.6-7.8 | 4.3-5.1 | 2.55-3.05 |

HXTA03 | 4.8-5.6 | 2.8-3.4 | 1.5-2.1 |

APPLICATIONS/应用场景:

l Semiconductor industry: Grinding and polishing of single crystal silicon wafers, siliceous wafers, piezoelectric quartz crystals, and compound semiconductors (gallium arsenide, indium phosphide). / 半导体行业: 单晶硅片、硅质晶圆、压电石英晶体、化合物半导体(砷化镓、磷化铟)的研磨抛光。

l Glass industry: Grinding and processing of crystal, quartz glass, picture tube glass screen, optical glass, LCD glass substrate, and piezoelectric quartz crystals./ 玻璃行业: 水晶,石英玻璃,显象管玻壳屏,光学玻璃,液晶显示器(LCD)玻璃基板,压电石英晶体的研磨加工。

l Coating industry: Special coatings and plasma spraying fillers. / 涂附行业: 特种涂料和等离子喷涂的填充剂。

l Metal and ceramic processing industry: precision ceramic materials, sintered ceramic raw materials, high-end high-temperature coatings, etc. / 金属和陶瓷加工业: 精密陶瓷材料,烧结陶瓷原料,***高温涂料等。

PACKAGE/包装:

10kgs/Bag+20kgs/Carton+1Ton/Pallet / 10公斤小袋+20公斤纸箱+1吨托盘

在线问

在线问