高纯度碳化硼粉末用于烧结陶瓷B4C 99.8% 1-2um

¥280.00

高纯度碳化硼粉末用于烧结陶瓷B4C 99.8% 1-2um

¥280.00

99.8%以上含量碳化硼微粉0.5um 用于B4C陶瓷件

¥280.00

99.8%以上含量碳化硼微粉0.5um 用于B4C陶瓷件

¥280.00

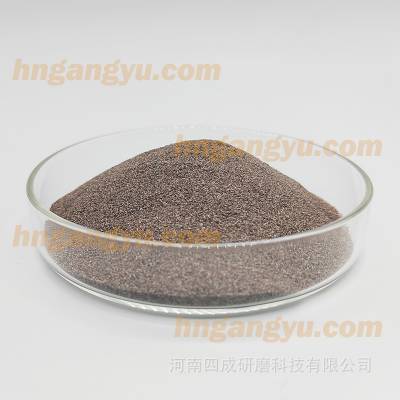

喷砂用金刚砂磨料一级金刚砂人造磨料F150 F180 Brown fused alumina

品名:棕刚玉

别名:金刚砂,人造金刚砂,棕色氧化铝砂,棕色电熔氧化铝

磨料代号:A,BFA

英文名称:Brown Aluminum oxide, Brown Fused Alumina, BFA grit, Brown corundum, Brown Alox, Electrocorundum 14A

喷砂用金刚砂磨料一级金刚砂人造磨料F150 F180 Brown fused alumina产品简介:

棕刚玉是铝矾土经过电熔后的人造磨料,它是一种主要成分为氧化铝的刚玉相非金属材料。棕刚玉大块的冶炼工艺分为倾倒炉和固定炉。破碎工艺分为对辊磨和巴马克球磨。分选工艺分为筛分和水洗溢流。筛分标准又分为F标标准和P标标准。棕刚玉的质量等级分为一级棕刚玉,二级棕刚玉,三级棕刚玉等等。因此,市场上的棕刚玉品质和价格相差很远。

一级棕刚玉的硬度和耐火性能是其中的***,通常用于喷砂研磨和制成磨具。棕刚玉的硬度接近白刚玉,比天然金刚砂高。棕刚玉的韧性比白刚玉好,体积密度高,自锐性磨削力略低,适合进行大规模的喷砂和快速研磨。棕刚玉适合的研磨对象为碳钢、铝合金、铁合金、各种非金属等。

Brown corundum is an artificial abrasive made from fused alumina, which is a non-metallic material with alumina as its main component. The smelting process of large brown corundum blocks is divided into pouring furnace and fixed furnace. The crushing process is divided into roller grinding and Bamac ball milling. The sorting process is divided into screening and water washing overflow. The screening standards are divided into F standard and P standard. The quality grades of brown corundum are divided into first grade brown corundum, second grade brown corundum, third grade brown corundum, and so on. Therefore, the quality and price of brown corundum on the market differ greatly.

The hardness and fire resistance of first-class brown corundum are among the best, and it is usually used for sandblasting, grinding, and making grinding tools. The hardness of brown corundum is close to that of white corundum and higher than that of natural diamond sand. Brown corundum has better toughness than white corundum, higher bulk density, and slightly lower self sharpening grinding force, making it suitable for large-scale sandblasting and rapid grinding. Brown corundum is suitable for grinding carbon steel, aluminum alloys, ferroalloys, various non-metallic materials, etc.

产品展示:

棕刚玉的主要技术指标:

主要矿物 | α-Al2O3 |

CAS编号 | 1344-28-1 |

莫氏硬度 | 9.0 |

显微硬度 | 2000-2200kg/mm2 |

熔点 | 2200 ℃ |

使用温度 | 1850℃ |

比重 | 3.95g/cm3 |

堆积密度(LPD): | 1.53-1.99 g/cm3 |

颜色 | 棕色,咖啡色,栗色 |

晶形 | 三方晶系 |

研磨级棕刚玉的特点:

1. 硬度高,切削能力强。

2. 纯度高,氧化铝含量93-95.5%,硅铁含量低。

3. 粒度均匀。棕刚玉的粒度分布符合FEPA标准,对各个筛网的颗粒占比都有严格的要求。细粉含量低。

4. 韧性好,颗粒抗破碎能力强。

5. 水溶性氯化物含量低,电导率低。

化学成分:

棕刚玉类型 | 型号 | 化学成分 | |||

AL2O3 | Fe2O3 | Si2O | Ti2O | ||

倾倒炉F砂 | F4-F80 | ≥94.5% | ≤0.25% | ≤1.0% | 2.0-3.4% |

F90-P150 | ≥94.5% | ≤0.25% | ≤1.0% | 2.0-3.4% | |

P180-P220 | ≥94% | ≤0.25% | ≤1.0% | 2.0-3.6% | |

固定炉F砂 | F8-F80 | ≥94% | ≤0.3% | ≤1.5% | 2.2-3.8% |

F90-F150 | ≥93% | ≤0.3% | ≤1.5% | 2.5-4.0% | |

F180-F240 | ≥92% | ≤0.3% | ≤1.5% | 2.5-4.0% | |

P砂 | P24-P80 | ≥94.5% | ≤0.25% | ≤1.0% | 2.0-3.4% |

P100-P150 | ≥94.5% | ≤0.25% | ≤1.0% | 2.0-3.4% | |

P180-P220 | ≥94% | ≤0.25% | ≤1.0% | 2.0-3.6% | |

微粉 | W63-W0.5 | ≥93.5% | ≤0.5% | ≤1.8% | ≤4.0% |

F230-F1200 | ≥93.5% | ≤0.5% | ≤1.8% | ≤4.0% | |

240#-3000# | ≥93.5% | ≤0.5% | ≤1.8% | ≤4.0% | |

棕刚玉的用途:

棕刚玉类型 | 用途 |

倾倒炉F砂 | 陶瓷砂轮,重负荷砂轮 陶瓷制品 |

固定炉F砂 | 合金压铸件,合金铸件,碳钢,模具钢,铜合金、铝合金、雾化玻璃、塑料、亚克力等材料的喷砂除氧化层、表面钝化、表面清理。 压铸厨具、钻杆、轴套、接头、轮胎模具、合金散热器、发电机叶轮、重型机械配件等材料的喷砂。 树脂砂轮 耐磨地坪、地坪砂浆 耐火骨料 |

P砂 | 涂附磨具 美甲工具 |

二级三级棕刚玉 | 大型喷砂 水刀切割 耐磨材料 |

棕刚玉的生产流程:

棕刚玉的包装:

在线问

在线问