- 防水防潮产品特性

- 是加工定制

- 塑料材料

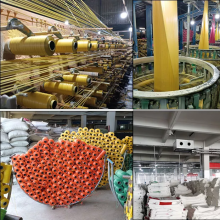

FIBC bags (Flexible Intermediate Bulk Container) are known by several names in the bulk bag industry, such as FIBC bulk bags, super sacks, bulk bags, totes, one-ton bags, and jumbo bags. Whatever name you know them by, they are used for moving dry products from one location to another.

There are many different types of FIBC bags to enable numerous dry products to be loaded safely. From simple to super complex specifications, these bags are sturdy enough to hold 5,000 pounds of dry material and transport it safely to a destination. Many industries use FIBC bags regularly, including the food, chemical, pharmaceutical, and mining industries, and many more.

Types of FIBC Bulk Bags

Type A

Used to transport non-flammable dry products. This type of Flexible Intermediate Bulk Container or bulk bag is not manufactured with any anti-static properties, so this type will not eliminate static electricity. This type of material is not safe to transport any dry product which could be explosive or flammable.

Type B

Type B Flexible Intermediate Bulk Containers are manufactured with insulating fabric and can be used with combustible dust with MIE greater than 3mj. However, this type cannot be used with any product containing flammable vapors or gases MIE <3mj.

Type C

Type C FIBC bags are used for safely shipping both combustible and flammable products. This bag has conductive threads laced throughout the material and must be electrically grounded with a wire to work properly. This type will eliminate the risk of static electricity.

Type D

This bag type is comparable to Type C bags, but due to the material construction, you are not required to physically ground the bag. Chromiq Blue material is the leading manufacturer of this material.

Always check with a certified FIBC bulk bag company to ensure you are using the correct bag type to reduce the chance of any safety issues. FIBCA also has really good information about the correct type of bag to use for your specific product.

Certified Flexible Intermediate Bulk Container (FIBC)

Food Grade Certified FIBC Bulk Bags

Certified Bags means the bags were made in a manufacturing facility that has been certified by a company licensed to audit the facility to ensure all safety protocols are being followed when manufacturing. Several companies will audit the plants to certify them as suitable to manufacture food-grade bags. Some are BRC, IFS, FSSC, and SQF.

Pharmaceutical Grade Certified FIBC Bulk Bags

Pharmaceutical FIBC bulk bags are manufactured with the most stringent processes to ensure there are no foreign materials in the bags when completed. These must go through an additional process to vacuum out, run through metal detectors, etc. There are thorough audits that must take place to certify a manufacturing plant to produce pharmaceutical FIBC bulk bags. We are able to make any custom bag you may need.

How many types of FIBC bags are there?

There are six main types of Flexible Intermediate Bulk Containers. They are circular, u-panel, four-panel, baffle bags, vented bags and dewatering bags. These are discussed below.

Circular

Circular bulk bags are the least costly bag to produce, as the body of the bag is made exclusively by machines. Essentially, they start with a tube and then sew on the type of bottom and top. These are durable bags, as they have fewer seams where issues can arise.

U-Panel

This design is like the four-panel bulk bag allowing it to keep its square shape while having less stitching. The less stitching you have on a bag, the less chance of a failure while loading and shipping the product. Therefore, this FIBC bag design will fall in between circular and four-panel bags regarding durability and maintaining more of a square shape.

Four-Panel

This bag is made using four separate panels which are then sewn together. This type of bag is going to maintain a better square shape vs. a circular bag. However, it will not support as much weight as a circular bag due to the additional sewn-in seams.

Baffle Bags

This type of FIBC bulk bag has baffles down the corners of the bag to allow material to flow into the baffles while loading. The bag only works with dry products which are small and flowable, as they must be able to load into the baffles without getting impeded. Plastic resin pellets, corn, soybeans, and rice are good examples of products that do well in these bags. The benefit of a baffled bag is that it will remain very square and allows solid stacking ability.

Vented Bags

This bag has special material which allows the bag to breathe and is good for food items such as potatoes, or other vegetables which may be prone to mold while transporting.

Dewatering bags

For special draining circumstances

Industrial Products Shipped with FIBC Bulk Bags

Mining

Mining is a perfect industry to utilize FIBC bulk bags, as mines are usually in a remote setting and tend to ship the product globally. These bags are ideal for this environment and can easily be transported out into the field, are easy to load, and are waterproof.

Minerals shipped in FIBC bags

Calcium carbonate

Magnesium hydroxide

Magnesium oxide

Talc

Sulfur

Molybdenum

Cobalt

Niobium

Copper

Tungsten

Pigments

Potash

Sodium bicarbonate (baking soda)

Graphite

Barite

Bentonite

Titan dioxide

Barium sulfate

碳酸钙吊带,是一种柔性运输包装容器,主要材料为PP和PE,它适用于装运袋装或散装碳酸钙,用于袋装碳酸钙长途或远洋运输。短途运输主要应用规格有1Ton, 1.5Ton,2Ton, 出口远洋运输主要规格为2Ton,本产品性能优良,具有防潮功能,也可以根据用户要求定制防水、防尘、耐辐射袋。5-7.5倍安全系数的特点,在结构上具有足够的强度, 集装卸、操作方便等特点,广泛用于矿产品行业的理想用品。

公司可根据用户需要如:不同袋装碳酸钙规格、运输距离、运输条件(陆运、海运、火车)、堆放条件、起吊次数、温度、运输周期等特点进行推荐和为不同客户进行度身定制。具体请垂询我司销售热线。

*集装袋(也叫吨袋,集装袋,大塑编袋,吊装袋,包装袋,子母袋,太空袋)是一种柔性包装容器.

*具有防尘、防潮、耐辐射、安全牢固等特点。

*在结构上有足够的强度,装填、卸出操作方便,适应机械化装卸。

*可广泛用于化工、水泥、粮谷、矿产品等各类粉状,粒状,块状物品的包装

*载重量0.5-3T;容积:500-2300L;保险系数可根据用户需要进行3:1;5:1;6:1设计。

*有圆筒形、方角形两种形状,具有单开口和上下开口适应一次性使用和周转使用不同需要的多种规格。

*防湿型集装袋使用聚乙烯内衬袋或涂膜加工材料。

*根据客户要求,集装袋上可印刷公司、品名等。

在线问

在线问

- 防水防潮

- 是

- 塑料

- 方型

- 方形集装袋

- 95*95*115