多轴钻床广泛应用于机械行业多孔零部件的钻孔及攻丝加工。

Multi axis drilling machine is widely used in drilling and tapping of porous parts in mechanical industry.

如汽车、摩托车多孔零部件:发动机箱体、铝铸件壳体、制动鼓、刹车盘、转向器、轮毂、差速壳、轴头、半轴、车桥等,泵类、阀类、液压元件、太阳能配件等等。多轴钻床可分为可调式和固定式两种规格,可调式多轴钻床在其加工范围内,其主轴的数量、主轴间的距离,相对可以任意调整,一次进给同时加工数孔。在其配合液压机床工作时,可自动进行快进、工进(工退)、快退、停止.同单轴钻(攻丝)比较,工件加工精度高、工效快,可***节约投资方的人力、物力、财力。尤其机床的自动化大大减轻操作者的劳动强度。固定式多轴钻床采用单件(加工件)专机的设计方案,根据其加工件加工频***、量大之原因,专门量身定制一件一机的设备,在其工作中勿须担心尺寸跑偏而伤脑筋。除用到常规的产品外,还可根据客户的特殊要求进行专项设计。

Such as automobile and motorcycle porous parts: engine box, aluminum casting shell, brake drum, brake disc, steering gear, wheel hub, differential case, axle head, half axle, axle, etc., pumps, valves, hydraulic components, solar energy accessories, etc. Multi axis drilling machine can be divided into two specifications: adjustable and fixed. Within its processing range, the number of spindles and the distance between spindles of the adjustable multi axis drilling machine can be adjusted at will, and the number of holes can be processed at the same time with one feed. When it works with the hydraulic machine tool, it can automatically fast forward, work forward (work backward), fast backward and stop. Compared with the single axis drilling (tapping), the workpiece has high processing accuracy and quick work efficiency, which can effectively save the manpower, material resources and financial resources of the investor. In particular, the automation of machine tools greatly reduces the labor intensity of operators. The fixed multi axis drilling machine adopts the design scheme of a single piece (processing part) special machine. According to the reason of high processing frequency and large quantity of processing parts, the equipment of one piece of one machine is specially customized. In its work, it is not necessary to worry about the size deviation and worry. In addition to the use of conventional products, but also according to the special requirements of customers for special design.

多轴钻孔机 手动两轴钻孔机 台钻 多轴器 手动钻攻两用机 多头钻孔机

¥5300.00

多轴钻孔机 手动两轴钻孔机 台钻 多轴器 手动钻攻两用机 多头钻孔机

¥5300.00

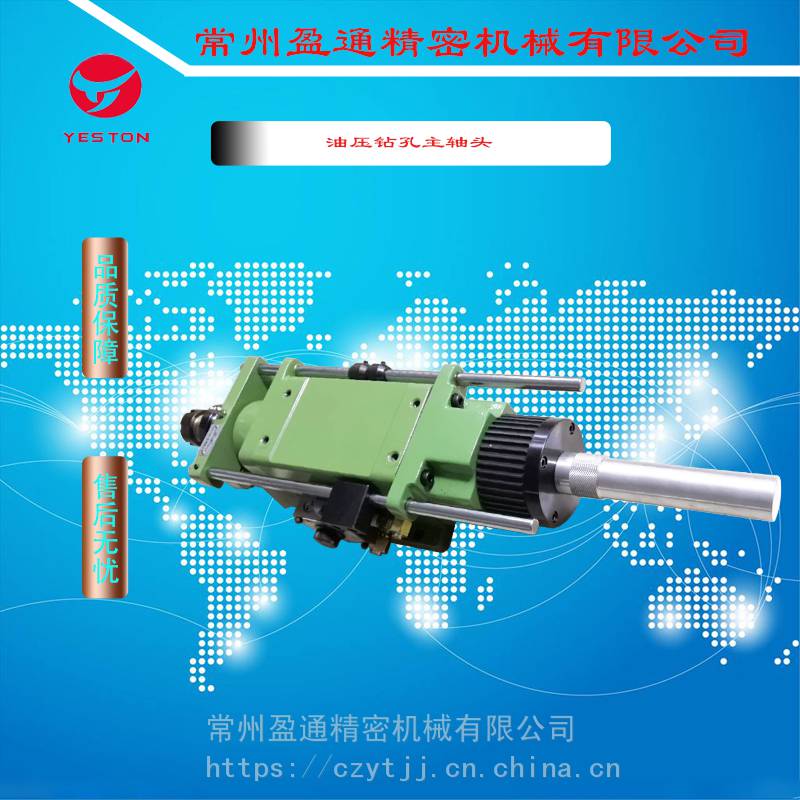

生产供应多轴攻牙机 自动攻牙机 多孔钻 多轴器 动力头 非标专用机床

¥23000.00

生产供应多轴攻牙机 自动攻牙机 多孔钻 多轴器 动力头 非标专用机床

¥23000.00

销售自动攻牙机 多轴器 动力头 多孔钻床 多轴攻牙机 工装夹具定做

¥11000.00

销售自动攻牙机 多轴器 动力头 多孔钻床 多轴攻牙机 工装夹具定做

¥11000.00

生产销售多孔钻床 液压钻床 多轴攻牙机 多头钻孔机 自动攻牙机 多轴器 组合钻床

¥18800.00

生产销售多孔钻床 液压钻床 多轴攻牙机 多头钻孔机 自动攻牙机 多轴器 组合钻床

¥18800.00

销售自动攻丝机 多轴攻牙机 多轴器 动力头 组合钻床 工装夹具 多孔钻

¥11000.00

销售自动攻丝机 多轴攻牙机 多轴器 动力头 组合钻床 工装夹具 多孔钻

¥11000.00