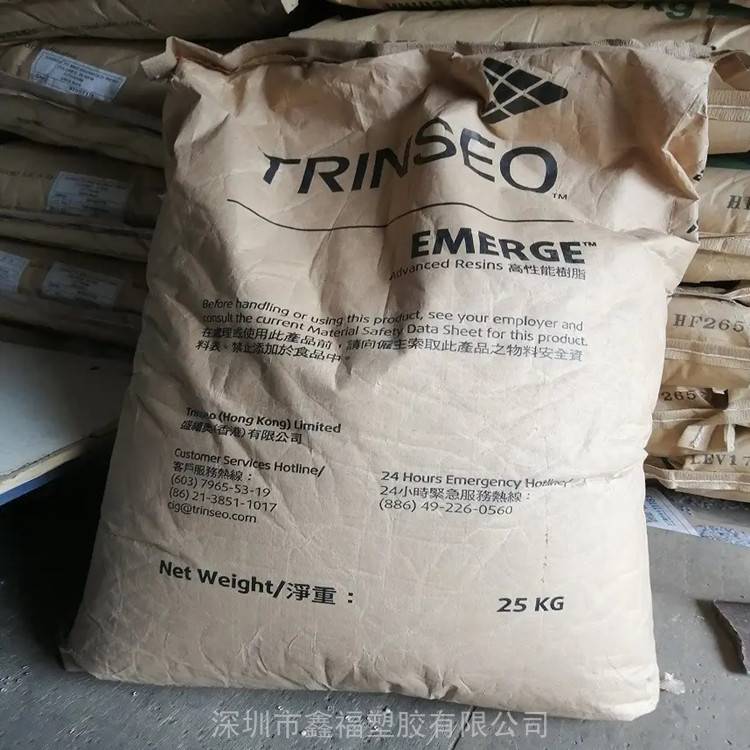

1.0mm无卤阻燃V0级EMERGE PC 8110-10盛禧奥

Density / Specific Gravity | 1.20 | g/cm³ | ASTM D792, *** 1183 |

Melt Mass-Flow Rate (MFR) (300°C/1.2 kg) | 10 | g/10 min | ASTM D1238, *** 1133 |

Molding Shrinkage - Flow | 0.50 to 0.70 | % | ASTM D955, *** 294-4 |

Tensile Modulus |

|

|

|

-- 3 | 2300 | MPa | ASTM D638 |

-- | 2400 | MPa | *** 527-1/1 |

Tensile Strength |

|

|

|

Yield 4 | 60.0 | MPa | ASTM D638 |

Yield | 60.0 | MPa | *** 527-2/50 |

Break 4 | 65.0 | MPa | ASTM D638 |

Break | 70.0 | MPa | *** 527-2/50 |

Tensile Elongation |

|

|

|

Yield 4 | 6.0 | % | ASTM D638 |

Yield | 6.0 | % | *** 527-2/50 |

Break 4 | 120 | % | ASTM D638 |

Break | 110 | % | *** 527-2/50 |

Flexural Modulus |

|

|

|

-- 5 | 2400 | MPa | ASTM D790 |

-- 6 | 2350 | MPa | *** 178 |

Flexural Strength |

|

|

|

-- 5 | 95.0 | MPa | ASTM D790 |

-- 6 | 95.0 | MPa | *** 178 |

Charpy Notched Impact Strength (23°C) | 35 | kJ/m² | *** 179/1eA |

Notched Izod Impact |

|

|

|

23°C | 700 | J/m | ASTM D256 |

23°C | 70 | kJ/m² | *** 180/1A |

盛禧奥EMERGE PC 8110-15无卤阻燃

¥34.00

盛禧奥EMERGE PC 8110-15无卤阻燃

¥34.00

半透阻燃EMERGE PC 8110-6盛禧奥

¥34.00

半透阻燃EMERGE PC 8110-6盛禧奥

¥34.00

盛禧奥EMERGE PC 8130-10阻燃抗紫外线

¥34.00

盛禧奥EMERGE PC 8130-10阻燃抗紫外线

¥34.00

抗紫外线高耐热EMERGE PC 8130-13盛禧奥

¥34.00

抗紫外线高耐热EMERGE PC 8130-13盛禧奥

¥34.00

阻燃抗紫外线EMERGE PC 8130-15盛禧奥

¥34.00

阻燃抗紫外线EMERGE PC 8130-15盛禧奥

¥34.00

盛禧奥EMERGE PC 8160-10防火V0

¥34.00

盛禧奥EMERGE PC 8160-10防火V0

¥34.00