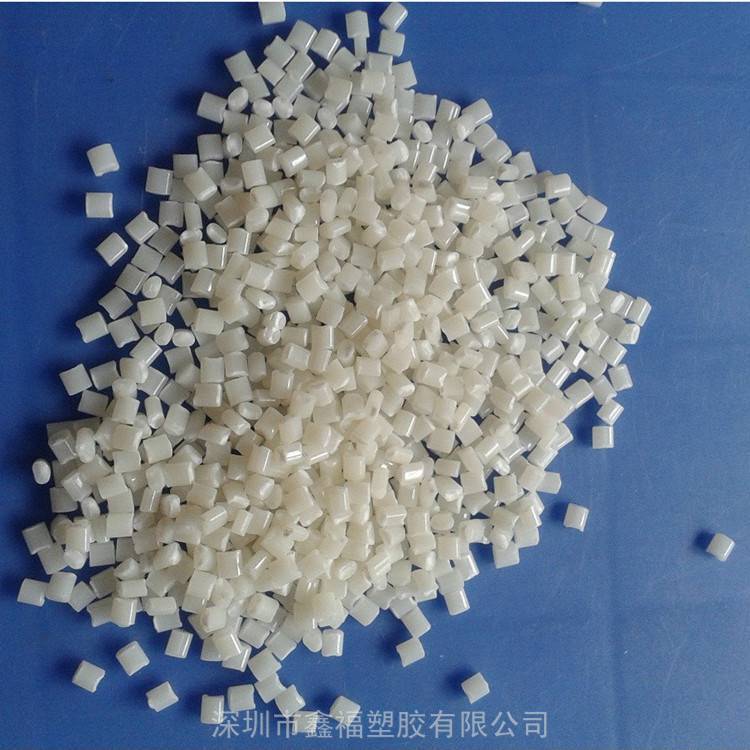

日本UMG电镀级ABS 3001M

Density(23°C) | 1.05 | g/cm | *** 1183 |

Melt Volume-Flow Rate (MVR)(220°C/10.0 kg) | 21 | cm/10min | *** 1133 |

Molding Shrinkage - Flow(23°C) | 0.40 to 0.60 | % | *** 294-4 |

| Hardness | Nominal Value | Unit | Test Method |

Rockwell Hardness(R-Scale, 23°C) | 109 |

| *** 2039-2 |

| Mechanical | Nominal Value | Unit | Test Method |

Tensile Modulus(23°C) | 2350 | MPa | *** 527-2 |

Tensile Stress(23°C) | 42.0 | MPa | *** 527-2 |

Flexural Modulus2(23°C) | 2500 | MPa | *** 178 |

Flexural Stress2(23°C) | 66.0 | MPa | *** 178 |

| Impact | Nominal Value | Unit | Test Method |

Charpy Notched Impact Strength |

|

| *** 179 |

-30°C | 11 | kJ/m |

|

23°C | 27 | kJ/m |

|

| Thermal | Nominal Value | Unit | Test Method |

Heat Deflection Temperature(1.8 MPa, Unannealed) | 81.0 | °C | *** 75-2/Af |

CLTE - Flow | 8.5E-5 | cm/cm/°C | *** 11359-2 |

| Flammability | Nominal Value |

| Test Method |

Flame Rating(1.0 mm) | HB |

| UL 94 |

ABS物料性能

1.综合性能较好,冲击强度较高,化学稳定性,电性能良好;

2.与372有机玻璃的熔接性良好,制成双色塑件,且可表面镀铬,喷漆处理;

3.有高抗冲、高耐热、阻燃、增强、透明等级别;

4.流动性比HIPS差一点,比PMMA、PC等好,柔韧性好;

5.适于制作一般机械零件,减磨***零件,传动零件和电讯零件。

UMG耐疲劳ABS 3001G

¥18.50

UMG耐疲劳ABS 3001G

¥18.50

UMG高流动电镀级ABS 3001MF2

¥18.50

UMG高流动电镀级ABS 3001MF2

¥18.50

UMG耐热电镀级ABS 3001MG2A

¥18.50

UMG耐热电镀级ABS 3001MG2A

¥18.50

UMG***流动ABS CE25

¥18.50

UMG***流动ABS CE25

¥18.50

UMG高抗冲ABS EX10U

¥18.50

UMG高抗冲ABS EX10U

¥18.50

UMG尺寸稳定ABS EX120

¥19.50

UMG尺寸稳定ABS EX120

¥19.50